- Ornaments0

- test-导入1

- 测试排序

- 家具用品11

- 宠物用品

- 家具用品3

- 家具用品2

- 玩具

- 装饰品

- 电子用品

- 家具用品

- 健身器材123

- 运动器材

- 健身器材

- Leisure and fitness equipment

- Finance and Insurance Industry

- Direct material supplier

- Lifestyle related topics

- Business use

- custom class

- qianqian-test16

- qianqian-test151as

- 产品分类8

- 产品分类7

- 产品分类6

- 产品分类5

- 产品分类1

- Auto Parts-test

- test 千千 With her love, I feel like a fish swimming happily in a beautiful sea.

- Industrial Hose

- filter paper

- tricycle

- Pet toys

- 颜色

- Food Rubber

- No picture classification

- Composite Rubbe

- Composite Rubber Hose2

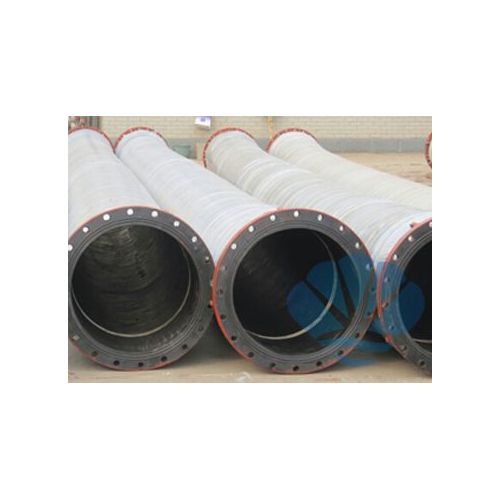

- Large Diameter

- Hydraulic Hose

Home

Products

Industrial Hose

High quality carbon steel chef's pan frying pan vegetable oil wok for cooking

High quality carbon steel chef's pan frying pan vegetable oil wok for cooking

Experience culinary excellence with our premium carbon steel chef's pan. Ideal for frying, sautéing, and stir-frying, this versatile wok delivers exceptional heat distribution and lasting durability. Whether you're a professional chef or a home cook, elevate your cooking game and create mouthwatering dishes effortlessly. Transform your kitchen today!

Product Description

Products Description

|

Product Name

|

Carbon steel wok

|

|

Material

|

Carbon Steel

|

|

Coating

|

Vegetable oil

|

|

Color

|

Customized

|

|

Handle

|

Iron

|

|

Usage

|

kitchen cooking

|

|

Packing

|

Color box+ master carton

|

|

Logo

|

Accept Logo Customized

|

|

Place of Origin

|

Hebei, China

|

Wok 32cm

Wok 34cm

Wok 36cm

Wok 38cm

Wok 40cm

OVER VIEW

CARTON STEEL P-1 -SERIES

CARTON STEEL P-2 -SERIES

CARTON STEEL Z-1 -SERIES

CARTON STEEL Z-2 -SERIES

CARTON STEEL P-3 -SERIES

CARTON STEEL Z-3 -SERIES

CARTON STEEL F-1 -SERIES

CARTON STEEL H-1 -SERIES

CARTON STEEL P-4 -SERIES

Production Process

Raw materials

The raw material for carbon steel pots is carbon steel, which is an iron carbon alloy with a carbon content between 0.0218% and 2.11%, also known as carbon steel. The main components of carbon steel, in addition to iron and carbon, also contain small amounts of silicon, manganese, sulfur, and phosphorus. The higher the carbon content of carbon steel, the greater its hardness and strength, but the lower its plasticity.

Material cutting

The cutting of carbon steel pot punch is an important step in the stamping process, which involves cutting or shearing carbon steel materials according to predetermined shapes and sizes for subsequent processing into metal products such as carbon steel pots. The following is a detailed introduction to the cutting of carbon steel pot punching machines:

Stretch forming

The stretching process of carbon steel woks not only involves plastic deformation of metal materials, but also involves multiple aspects such as material selection, mold design, and control of forming processes. Through reasonable process design and operation, carbon steel woks with different shapes and excellent performance can be produced to meet the needs of different users.

Polishing and Grinding

Polishing and Grinding: Firstly, for the polishing and grinding of cast iron pots, angle grinders can be used in conjunction with different types of brush heads for processing. The specific steps are as follows:

Nitridation

The nitridation treatment of cast iron pots is a treatment technology that forms a nitride iron layer and an iron oxide layer on the surface of the pot through a special process, aiming to improve the wear resistance, corrosion resistance, and anti sticking effect of the pot, as well as improve its thermal conductivity and non adhesiveness.

Vegetable oil

It is a common practice to use vegetable oil for rust prevention treatment in cast iron pots, mainly utilizing the natural,non-toxic,environmentally friendly, and safe characteristics of vegetable oil, as well as its good permeability and film-forming properties.

Riveted packaging

The riveting process of an iron pot mainly involves using rivets to firmly connect the pot cover to the pot body, ensuring the safe and durable use of the pot. Color packaging: Different materials and processes can be customized according to customer needs for

packaging selection.

packaging selection.

The finished product stacking area

The finished product stacking area is a dedicated area for storing products that have completed the production process. The main purpose of this area is to ensure the safe storage of products and avoid damage or contamination during storage and transportation

Certificate

Test Report

Company Profile

Our Company

Tangshan Baihan Houseware Co., Ltd. is located in the central area of the Beijing, Tianjin and Tangshan city, which is located on the banks of the Huanxiang River in Yutian County, Hebei Province. We are a professional enterprise engaged in the research and development, manufacturing, marketing, and brand operation in the field of high end cookware products. We are committed to building a "Chinese cookware supply aircraft carrier" and producing and operating various series of high standards products including carbon steel woks, cast iron woks, aluminum pots, stainless steel pots, etc .

Company Exhibition

Packing

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1: Are you factory or trading company?

A: We are the factory. We are the source! You can check full view of our factory.

Q2: How long is your delivery time?

A: 25-35 workdays after all information confirmed(According to different products)

Q3: What is your after-sale service?

A: Free spare parts of 0.5% products price and comes with a full 1 year warranty.

Q4: Do you provide samples? is it free or extra? how long did you provide to me?

A: We can supply existing free sample, but customer need to respond for the freight. Normal products take 1 days, special

3-5days,open mold products 7-15 days.

Q6: How can I get a quotation from your company?

A: Send your message to our sales in the input box below, we will reply you within on hour on working day. Or you can contact us

directly by Trade Manager (click Chat Now on the right side of this page).

A: We are the factory. We are the source! You can check full view of our factory.

Q2: How long is your delivery time?

A: 25-35 workdays after all information confirmed(According to different products)

Q3: What is your after-sale service?

A: Free spare parts of 0.5% products price and comes with a full 1 year warranty.

Q4: Do you provide samples? is it free or extra? how long did you provide to me?

A: We can supply existing free sample, but customer need to respond for the freight. Normal products take 1 days, special

3-5days,open mold products 7-15 days.

Q6: How can I get a quotation from your company?

A: Send your message to our sales in the input box below, we will reply you within on hour on working day. Or you can contact us

directly by Trade Manager (click Chat Now on the right side of this page).

WeChat

-

自定义客服1: 7890988

-

自定义客服2: 6789088

-

自定义客服3: 7890988

-

自定义客服4: 6789088